Cost Effective Single Head CNC Drilling Machine for Sale for Cabinet Making

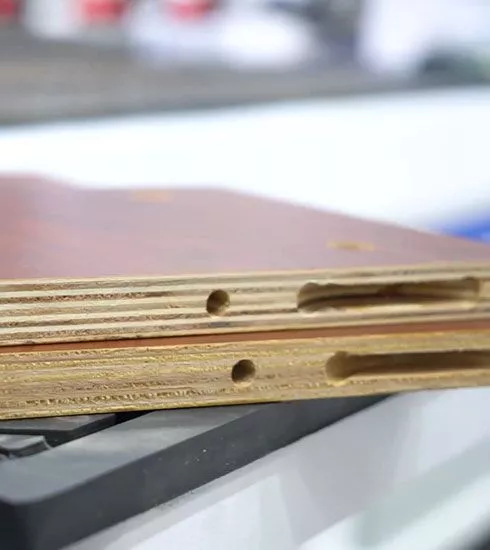

☆This is an entry-level CNC side drilling machine for drilling side holes, dowel holes, blind holes, and making slots on the sides of wooden panels in the furniture production. It is a high cost-performance ratio and can meet the drilling demands of small cabinet making businesses.

Wood Drilling Machines Video

Features

- The custom limits provide safety protection for the processing.

- It uses laser scanning to accurately locate and intelligently determine the punching position.

- It is very cost-effective for small cabinet-making manufacturers.

Parameters

| Model | ELE100 |

| Spindle | 2.2kw Changsheng air cooling spindle |

| Spindle speed | 0-18000RPM/MIN |

| Traveling speed | 10-120 m/min |

| Working speed | 10-80 m/min |

| Effective travel of table | 2800 mm |

| Height of table | 750 mm |

| Drive and motor | servo motor and drive |

| Sensor | BANNER |

| Controller | QIYUE |

| Guild | #20 square rail |

| Rack | Taiwan JUELI |

| Screw | TBI |

| Electrical elements | Schneider Electric |

| Whole size | 3300*1250*1300mm |

| Whole weight | 1100kg |

Application

Side drilling machines are mainly used to drill side holes or make slots or grooves on side surface of wooden panels. It is designed with simple structure and easy operation. We provide three major side drilling machine models for now. The major difference between them is the number of drill bits or saw blade that they have. All three models of side hole drilling machine have three work stations, which enables to process three panels at the same time. It greatly improves the side drilling efficiency.

Production Facility

Quality Control & Testing