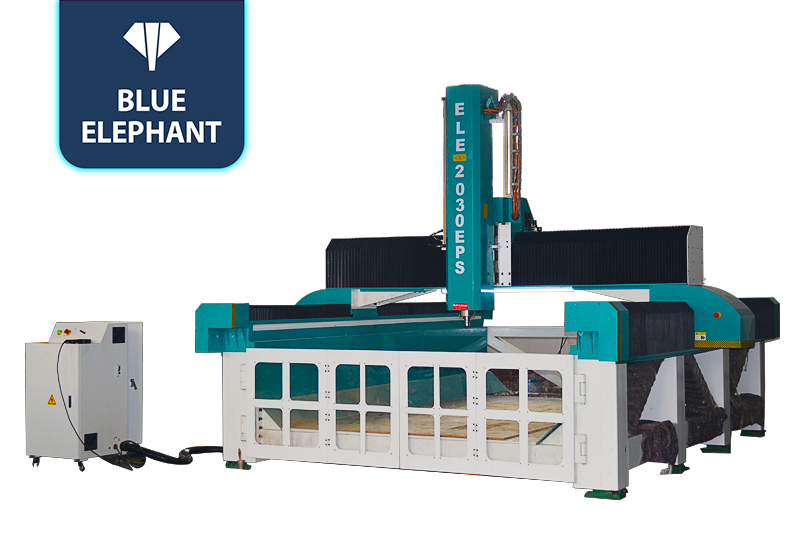

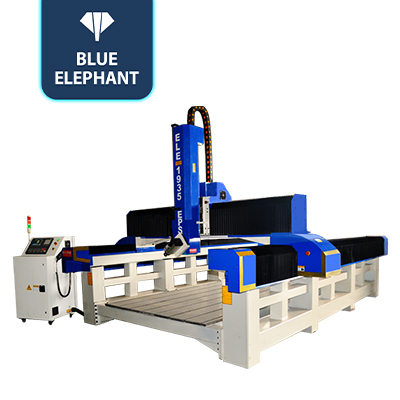

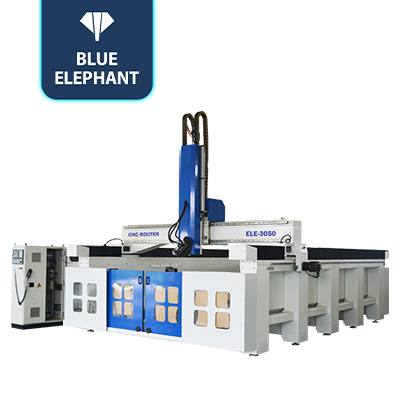

Best 2030 3D EPS Styrofoam Cutting Machinery Price

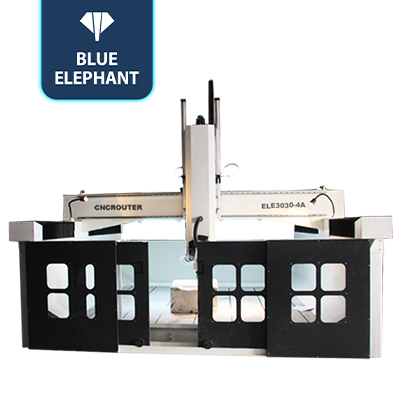

☆This 3D CNC foam cutter is tested to the limit for robustness and reliability. It is the first choice for customers who need to process large workpieces.

CNC Router Machines Video

features

- Adopt a 7.5kw Changsheng water-cooled spindle to ensure maximum processing efficiency.

- Working size can be customized.

- It adopts NK 105 control system, which has the function of resuming transmission from breakpoints and high precision.

Parameters

| Model | ELECNC2030 EPS |

| X,Y axis travel | 2000x3000mm, option: 1500*3000mm; 2100*3000mm; 2100*4000mm, etc |

| Z axis travel | 8000mm, option: 900mm, 1000mm, etc |

| Spindle type | 7.5KW water cooling spindle |

| Inverter type | 7.5kw Fuling Inverter |

| Control system | Weihong NK105 controller with hand wheel guide |

| Driving system | 850KW YASKAWA servo |

| Reducer | Japan SHIMPO reducer |

| Machine structure | Heavy duty body with quenching treatment |

| Work table | Aluminum T-slot work table with PVC Protection |

| Linear guide | Taiwan linear guide with dust proof |

| Transmission | X,Y axis: Taiwan / Germany Helical Rack and Pinion Z axis: Taiwan TBI high precision ball screw |

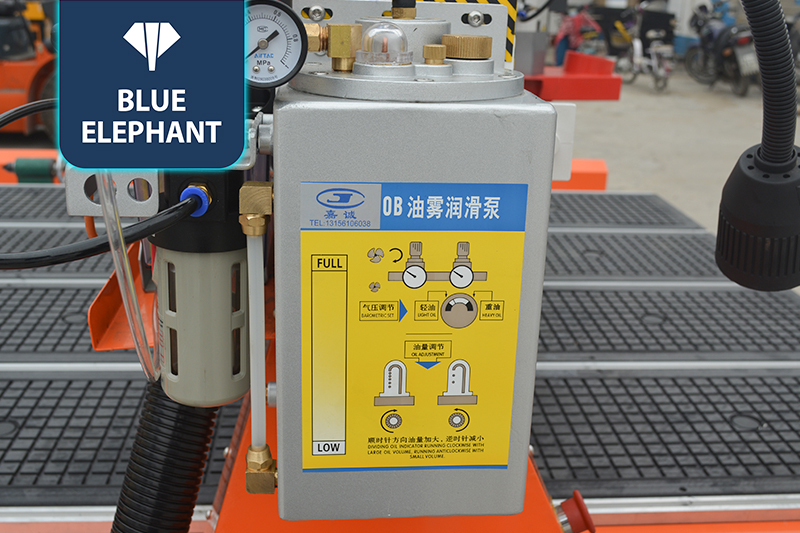

| Lubrication system | Manual lubrication system |

| Tool calibration | Manual tool sensor calibration |

| Cables | Germany Igus cables with CE, cUL certificate |

| Compatible software | Artcam, Type 3, Ucancam, Aspire, etc |

| Command language | G Code & M Code |

| Traveling speed | 60m/min |

| Working speed | 0-45m/min |

| Re-positioning accuracy | ±0.03mm |

| System resolution | ±0.0025mm |

| Working accuracy | ±0.03mm |

| Working voltage | 220V 1PH/3PH 50HZ/60HZ 380V 3PH 50HZ/ 60HZ |

Application

Mold industry: It can be used in the precision production of various cast wood molds for automobiles, ships, aviation, trains, etc.

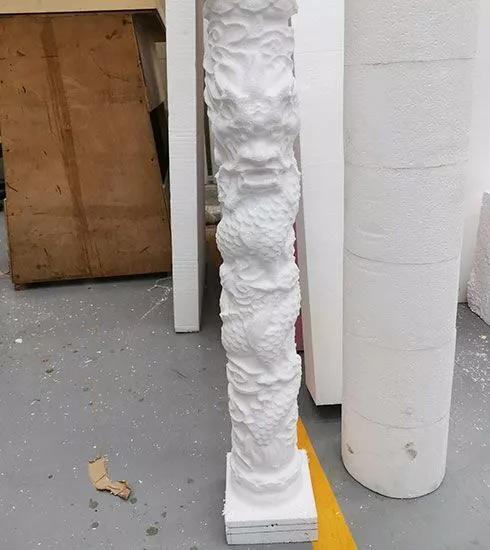

Casting sculpture industry: various casting craft products, lost foam, exhibition decoration materials.

Building decoration industry: processing and production of building decoration materials such as GRG and GRC.

Production Facility

Quality Control & Testing