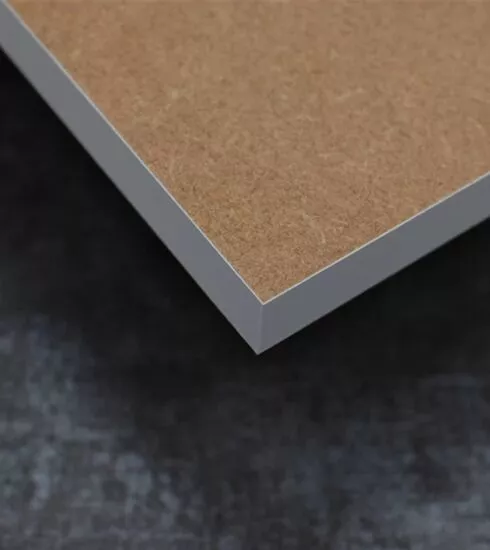

The Best Edge Banding Production Line is Sold to UK, France, Yemen at an Affordable Price

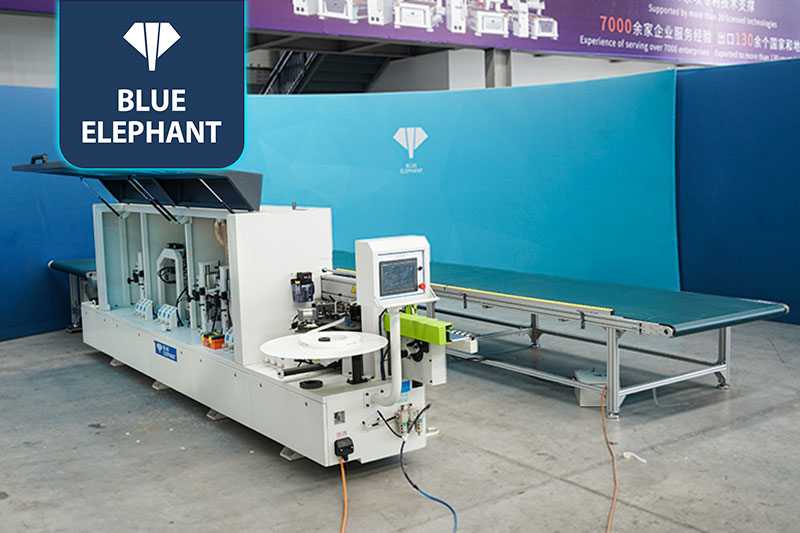

☆The automatic edge banding production line consists of a fully automatic edge banding machine and multiple auxiliary belt conveyor platforms. Higher efficiency and saving labor costs.

Edge Banding Machines Video

features

- The production line consists of an automatic edge banding machine and multiple belt conveying platforms, which is easy to operate, improve processing efficiency, and reduce manual operations.

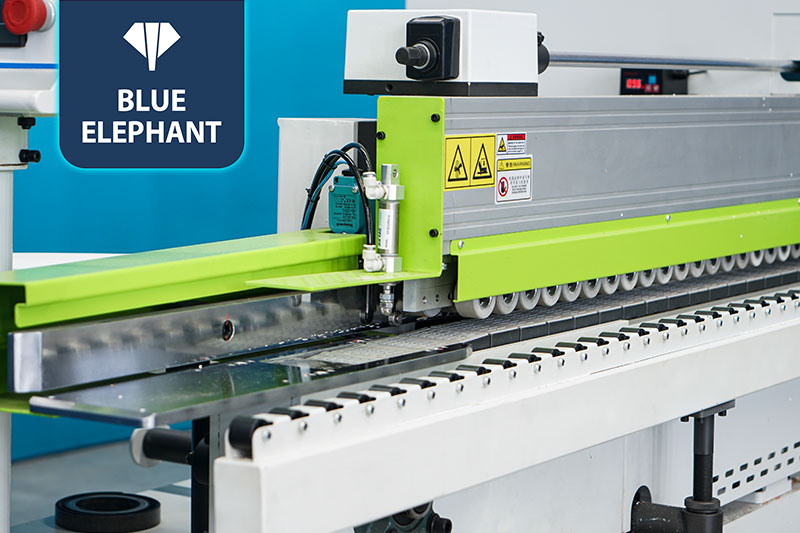

- It can complete various complex tasks such as gluing, binding, end cutting, rough repair, fine repair, contour tracking, scraping, polishing, etc.

Parameters

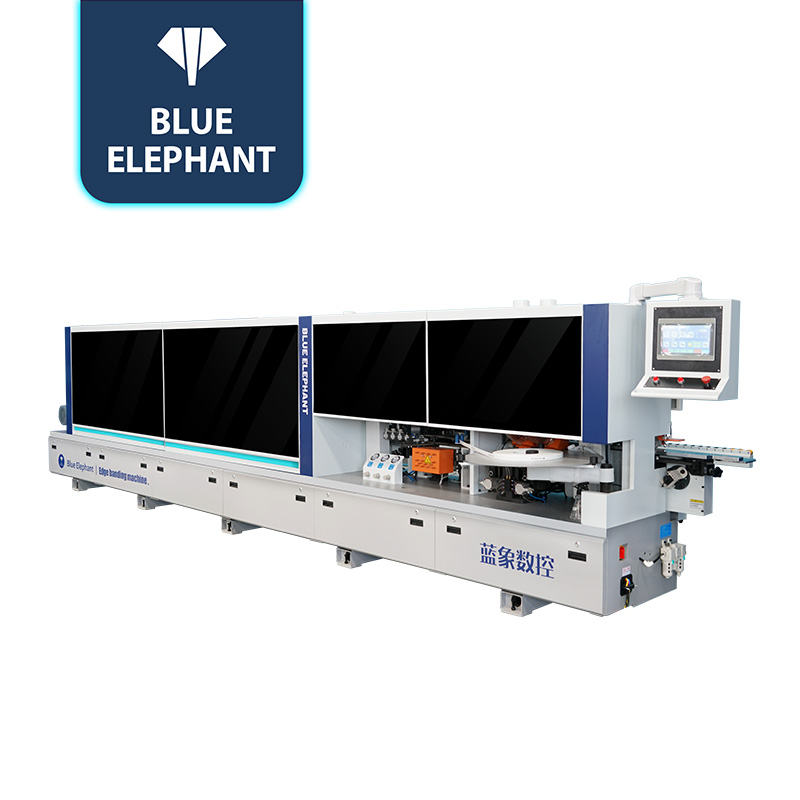

| Total power | 10.8kW |

| Dimension | 5600*960*1600mm |

| Feeding speed | 16-23m/min |

| Thickness of edge band | 0.4-3mm |

| Thickness of wood board | 10-60mm |

| Length of wood board | ≥150mm |

| Width of wood board | ≥60mm |

| Working pressure | 0.6Mpa |

Application

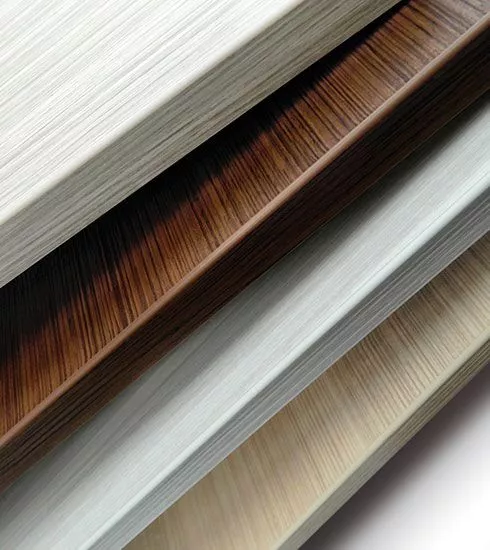

The edge banding machine is mainly used for edge banding of various panel furniture. For example, cabinets, wardrobes, custom furniture, office furniture, tables, doors and other millwork.

Production Facility

Quality Control & Testing